When challenges arise, Invent Automation creates solutions

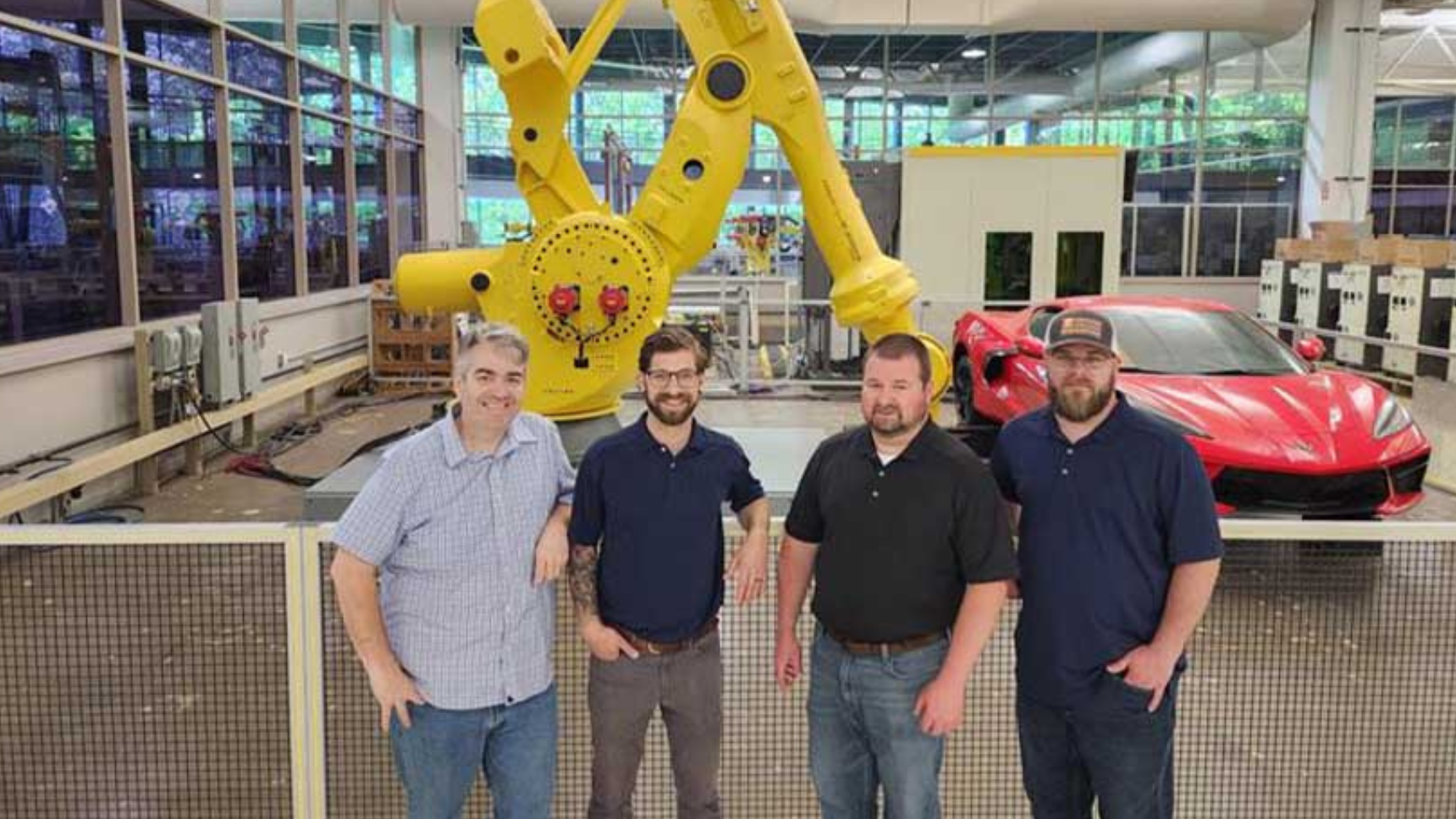

A team of 16 engineers spend their days imagining, designing, and building custom automation for manufacturers using the latest in AI to high-speed robotics.

Have you ever had a problem you just can’t fix? Well, we know a guy.

Adam Nelson founded a company around his unique ability to solve just about any problem, specifically when it comes to manufacturing.

Invent Automation creates custom machines, robots, and work cells that alleviate pain points for manufacturers of any size. They have built custom technology solutions for companies as big as Denso, DeRoyal Industries, and Swiss Technologies, down to small-scale, local mom-and-pop shops.

“Most manufacturing companies have the mindset of continuous improvement. We take their problems and invent automation to solve the problem and allow them to do more with less,” Nelson said.

Nelson launched the company first in 2014 as SolVIS Automation; however, as they continued to grow in popularity, Nelson changed the name to Invent Automation to better represent what they do.

“We are inventors in the manufacturing space. We love manifesting from our minds and bringing our ideas into the world,” Nelson said.

His team of 16 engineers spend their days imagining, designing, and building custom automation for manufacturers using the latest in AI to high-speed robotics.

Once a design is approved and engineered, they order the parts and begin the construction of the one-of-a-kind machine.

“It’s like tinker toys… except a lot more complex,” Nelson said. “Doing custom automation is the pinnacle of manufacturing. It requires a lot of expertise, wisdom, and creativity to do what our team does.”

Nelson is a highly skilled engineer with a creative career spanning decades. He shared how he began tinkering with CAD when he was 11 years old, secured a job as a design engineer at 15, and ultimately worked his way through college where he got degrees in Industrial Engineering and Manufacturing Engineering. But nowadays his business card just reads Inventor/Owner.

Through the years, he has worked as an Operation Manager for major manufacturing and engineering firms, even working up to the role of Owner and Chief Executive Officer (CEO) of NEI, an aerospace company in California. When he sold the company in 2009, Nelson knew it was time for him to step into his calling as an inventor where he had cut his teeth earlier in his career.

Today, Invent Automation is known as one of the most innovative robotics, custom machine, and machine vision companies in Tennessee. In the past ten years, the company has designed and deployed countless automated machines, and machine vision systems, all out of its 10,000-square-foot facility.

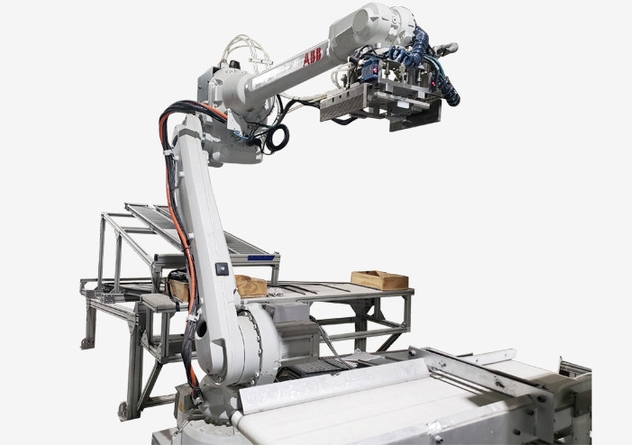

Most recently, they recently completed a robot for Swiss Technologies in Knoxville. Swiss Technologies produces millions of precision parts each year, some smaller than the size of a coffee bean.

It would take a keen eye to inspect faults in parts that are that small. Can you imagine looking at each piece with the naked eye? It’s physically impossible.

However, Invent Automations’ custom-made technology, harnesses the power of machine vision and robotics to find the faulty pieces.

“There is no other machine exactly like this in the whole world,” Rick Jones, Swiss Technologies’ Owner and General Manager, told Teknovation.biz during an interview in June. “It was custom-made for our facility and can inspect a part every two seconds. It can inspect seven million parts per year.”

Nelson shared his joy, and sense of accomplishment with how the machine turned out.

“It all starts with being a good listener. I think that’s what really makes us successful,” he said.

Invent Automation recently went through an expansion of its offices and facility off Midpark Drive in West Knoxville, making space to add employees, create bigger machines, and handle more projects.

Learn more about Invent Automation and the other recent projects.

Like what you've read?

Forward to a friend!