IC COHORT 6 | Captis Aire focused on commercializing Fluidized Bed Concentrator capture technology

(EDITOR’S NOTE: This is the third article in a series spotlighting the members of Cohort 6 of the “Innovation Crossroads” program operated by Oak Ridge National Laboratory.)

(EDITOR’S NOTE: This is the third article in a series spotlighting the members of Cohort 6 of the “Innovation Crossroads” program operated by Oak Ridge National Laboratory.)

By Tom Ballard, Chief Alliance Officer, PYA

There’s a lot of meaning in the name that Kim Tutin gave to Captis Aire LLC, the start-up that she is leading as part of Cohort 6 of the “Innovation Crossroads” (IC) program operated by Oak Ridge National Laboratory (ORNL).

“Captis is Latin for capture, and Aire refers to the turpentine we are capturing from the air,” she told us in a recent interview. The Founder and Chief Executive Officer of the company has more than 20 years’ experience in R&D and commercialization at Georgia-Pacific. Since 2015, she’s been working to develop and commercialize the Fluidized Bed Concentrator (FBC) capture technology for use in wood drying applications.

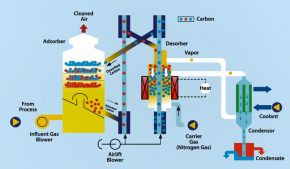

That capture technology (depicted here) is at the center of where Captis Aire sees a significant business opportunity, one that has both economic and environmental benefits.

That capture technology (depicted here) is at the center of where Captis Aire sees a significant business opportunity, one that has both economic and environmental benefits.

“Wood products manufacturers are required to control the organics coming out of the wood,” Tutin explains. “To control these organics, they use a boatload of natural gas. We even refer to these systems as ‘gas guzzlers.’ Instead, our capture technology uses activated carbon to collect them (the organics) rather than burn them.”

She draws a comparison between Captis Aire’s process and the refrigerator filter that is used to make sure water for ice and drinking is as clean as it can be. That’s what the FBC does in the wood drying process, using activated carbon to capture volatile organic compounds and hazardous air pollutants.

In addition to providing a capital and energy efficient emissions capture technology that improves the efficiency of wood drying processes and reduces greenhouse gas emissions, the technology also results in another revenue stream from selling the turpentine that is a byproduct of the process.

“We clean the air and collect the turpentine,” Tutin says. The Minnesota native spent more than 34 years at Georgia-Pacific before deciding in 2020 to license the technology from Georgia-Pacific Chemicals and devote herself full-time to Captis Aire.

“We clean the air and collect the turpentine,” Tutin says. The Minnesota native spent more than 34 years at Georgia-Pacific before deciding in 2020 to license the technology from Georgia-Pacific Chemicals and devote herself full-time to Captis Aire.

“We’ve been bootstrapping since the end of 2020,” Tutin says.

With two successful demonstrations completed at a commercial wood products manufacturing site, she became interested in the IC opportunity. “The more I learned, the more convinced I was that we were a good fit,” she says of ORNL’s capabilities in the Energy and Industrial Decarbonization Section and the Carbon and Composites Group supported by the Department of Energy were key reasons.

Tutin identified three goals for the two-year IC Fellowship.

- She wants to launch another demonstration with a commercial wood products manufacturing company. “I want to show the world it (the technology) works and also show them (the company) that it works on their site,” Tutin explains.

- She wants to leverage ORNL’s vast research capabilities. One example involves determining how to extend the life of the activated carbon.

- Finally, Tutin wants to maximize the value of the turpentine, initially converting it to sustainable aviation fuel. “We have done some preliminary work with the University of Dayton and the U.S. Navy,” she says, adding, “Beyond aviation fuel, there are quite a lot of other uses.” Those include everything from fragrances to solvents, agricultural applications, cleaners, and more.

Like what you've read?

Forward to a friend!