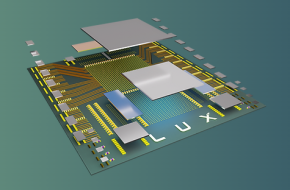

Lux Semiconductors is a pioneer in the use of metal as a material for substrates

The alum of the "Innovation Crossroads" program is at the forefront of the a move from chips to chiplets.

Describing the company he co-founded as “a pioneer” in the use of metal as a material for substrates, Shane McMahon says he hopes that Lux Semiconductors can start low-volume manufacturing in the next two years.

We first met the then-recent graduate of the State University of New York at Albany when he joined the second cohort of the “Innovation Crossroads” program operated by Oak Ridge National Laboratory in 2018. Both McMahon and Don DeRosa, Co-Founder and Chief Executive Officer of Eonix, earned their doctorates from the same institution at the same time and relocated from update New York to Knoxville to join “Innovation Crossroads.”

More importantly for the region, neither had lived in the South before moving here, but both have remained after their two-year fellowship ended in 2020. And, in the case of Lux Semiconductors, McMahon, a native of Halfmoon, NY, wants Knoxville to be on the short list of places where that low-volume manufacturing could be done.

“I love it here,” he says. “I like the culture, people, and weather. Something is happening in Knoxville.”

It had been several years since we caught up with McMahon to learn about developments with Lux Semiconductors.

“We had a major inflection point four years ago,” he reminded us. That was about the time the “Innovation Crossroads” Fellowship ended. “We had been working on a low-cost sensor and made a pretty significant technical pivot at the end of the program.”

The driver was something called Moore’s Law. Named after Gordon Moore, Co-Founder of Fairchild Semiconductor and Intel, it has propelled the rapid growth of the high-performance computing industry.

How so? Moore observed that the number of transistors in an integrated circuit board doubles about every two years.

“Moore’s Law is slowing significantly,” McMahon says.

Why?

The semiconductor industry has encountered major challenges in continuing to make transistors smaller as it approaches the physical limits. This has motivated a move from chips to “chiplets” for at least two reasons. First, there’s an economic benefit in terms of manufacturing. Second, there are performance improvements.

The focus of Moore’s Law was on the chip, but that has now shifted to the substrate.

“The move from chips to chiplets requires a higher performance substrate,” McMahon says, and that transition that started five years ago is where Lux Semiconductors is focusing its efforts. “What was Moore’s Law of transistors is now becoming Moore’s Law of packaging, connecting chiplets on advanced substrates.”

About its use of metal, McMahon explained that substrates made of organic materials tend to trap heat and warp. Lux Semiconductor’s use of metal for substrates solves both of those problems.

“Lux has been granted a couple of patents around the use of metal for advanced substrates,” he says.

The company is developing its metal substrate at a prototype level at the Cornell NanoScale Science and Technology Facility and Lux Semiconductor’s 4,100-square-foot lab, both in Ithaca, NY. That’s where Co-Founder Graeme Housser is based. He serves as Chief Technology Officer, while McMahon is the Chief Executive Officer.

Since its founding seven years ago, the company has raised $6 million in government grants and $2.3 million in seed funding with a Series Seed round soon to be underway with a target of $6 million.

Like what you've read?

Forward to a friend!