Knoxville manufacturer cracks the code for retention: Treat your people great

As a result of growth, Knox Wire Harnesses just moved into a newer, bigger building off Anderson Avenue in north Knoxville.

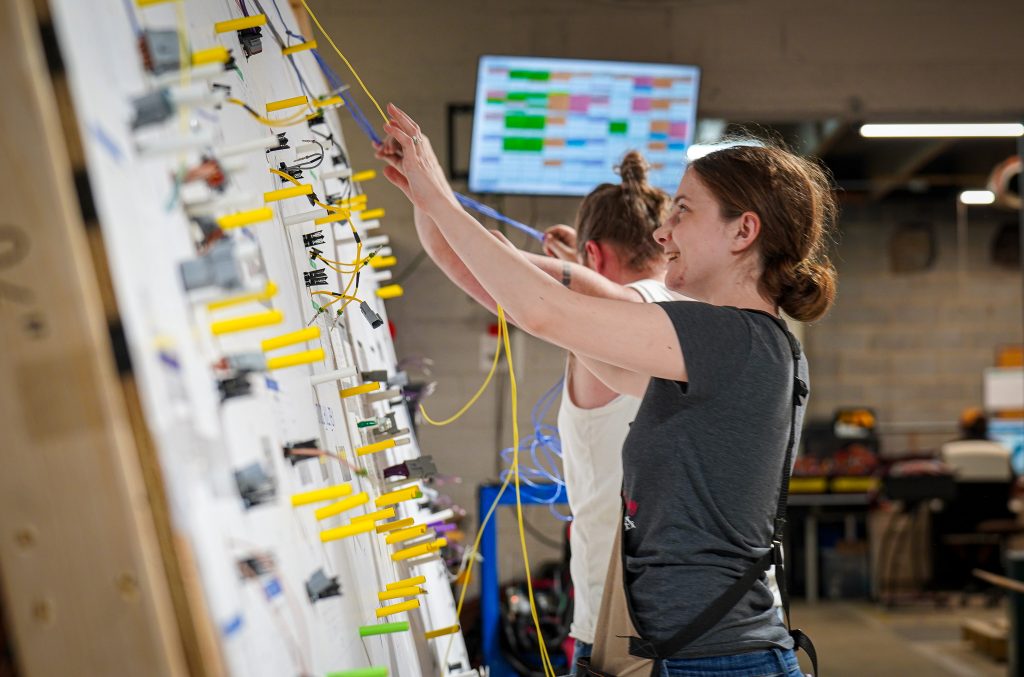

“You asked me what I’m most proud of?” Rob Brown asked. He turned and gestured toward his 30 employees, all smiling, laughing, and gathered around Knox Wire Harnesses’ assembly stations. “This is what I’m proud of.”

Knox Wire Harnesses (KWH) has been around since 2019, and it has grown in both production and people since then. After touring their brand new facility to learn the “secret sauce” behind the company’s success, several factors became evident. The manufacturing “plant” is unlike any we’ve ever seen, the people come from diverse backgrounds- with little to no experience in manufacturing, and yet they work together like a well-oiled, highly efficient machine.

Brown said it’s the company culture and comradery that makes KWH so great.

However, the employees say the “secret sauce” is Rob Brown.

While most manufacturing companies across the nation are struggling to recruit and retain talented people, KWH seems to have the opposite. They have people eager to work for them.

“Since 2019, we have had almost no turnover because people here love each other, many of them knew each other previously, and all of them are grateful to be here,” said Mikey Bishop, the Assembly Manager.

“Everyone has great energy and is encouraging of one another’s personal and professional goals,” said Matt Neubill, the Pre-assembly Manager.

Additionally, any issues with processes are solved by the team, for the team.

“We work to solve problems as a team and are constantly asking for feedback on how to make this place, and the processes better,” Bishop said.

That method of feedback is how KWH concocted its very innovative assembly process.

“We had people come from food service, hospitality, and various other industries who had no idea how to make a wire harness, let alone what a wire harness was. So, those same people put their heads together to design an assembly process that was easy to teach, use, and read,” Bishop said.

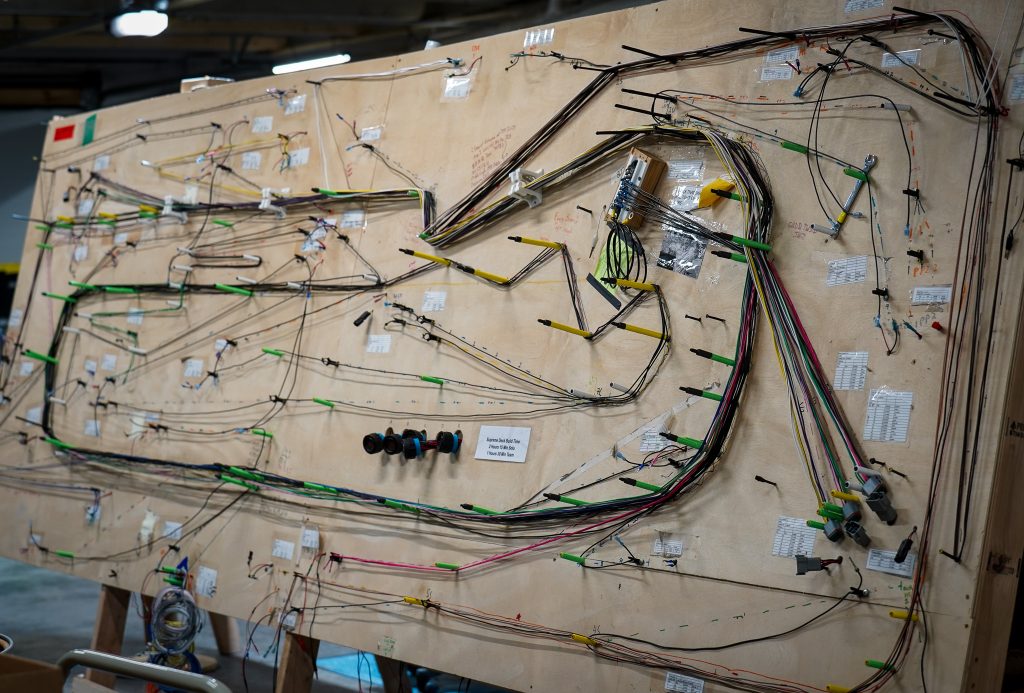

A wire harness is a system of wires or cables that are bundled together and organized within an insulating material to transmit electrical power or signals. KWH makes harnesses for all types of automated products; however, some of their biggest customers are boating companies.

One of the things KWH has focused on over the years has been developing a quality assurance system that checks everything. Part of that is electronically checking every harness individually. They have done this for years by plugging a computer into the boards they develop to ensure every wire works the way it’s supposed to.

However, doing this level of quality assurance certainly slows down production. The old method of assembly highly depended on the assembler to know what they were doing.

The new assembly method has labels, plugs, cheat codes, and a full-scale visual model for what the finished product needs to look like.

“This was envisioned by people in this building. We leaned on their creative skillsets instead of hiring an outside company,” Bishop said. “That helped employees feel invested in the company on a whole other level.”

Through the new method, they can produce up to 100 wire harnesses per week.

Brown started the business after working as a government employee for the Navy. He was an engineer who built battery harnesses alongside one of his friends, later- business partner, Will Nichols. They decided to move full-time into building bigger harnesses. Their first client was Local Motors, then the business grew into servicing almost exclusively massive wakeboard companies.

“We have turned down more work than we have accepted,” Brown said. “We would rather turn down work and keep our quality and work culture high.”

So, when talking about growth plans, Brown said something rather unexpected.

“We don’t want to take it to the moon, we want it to take us,” Brown said. “The growth is to be determined, based on values.”

He places his people before anything else, and Brown isn’t interested in growing beyond a point where company culture suffers at the expense of business.

Brown said the Knoxville community has been vital to KWH’s success. Specifically, Brown pointed out that the Tennessee Manufacturing Extension Partnership (MEP) Peer Support Group has been game-changing for his company.

“I would go as far as to say it has been the most beneficial thing I have ever done for my business,” Brown said. “It has been amazing to hear from people who have bigger plants, who have more employees and have been doing this a lot longer than we have. They have great advice and I have learned so much.”

The group meets once a month at the Institute for Public Service building off University Avenue.

One of Brown’s biggest takeaways from the group was to prioritize culture – which he has proven to do time and time again. In fact, Brown soon hopes to transition KWH into an employee-owned business model to support his people and their professional development even further.

“Rob has taken a chance on all of us,” Bishop said. “He’s a true leader and we’re lucky to work for him.”

Like what you've read?

Forward to a friend!