3D Solar revolutionizes the way we capture solar energy

3D Solar has enhanced energy capture with increased surface area and are designed for decentralization and independence.

The “Techstars Industries of the Future Accelerator“ is currently abuzz, housing what is rumored to be its most innovative group of participants since its establishment in Knoxville three years ago. The third cohort is replete with high-tech companies ready to unveil groundbreaking innovations in their respective fields. Each participant, marked by intelligence and grand visions, is set to change the world with their unique products and services.

Daniel Clark, the visionary founder of Topshelf Enterprises DBA 3D Solar, stands among this distinguished group. Clark is revolutionizing the solar energy sector with a highly efficient method for harnessing solar power. He has crafted a novel three-dimensional solar cell/panel that maximizes energy production within a minimal footprint.

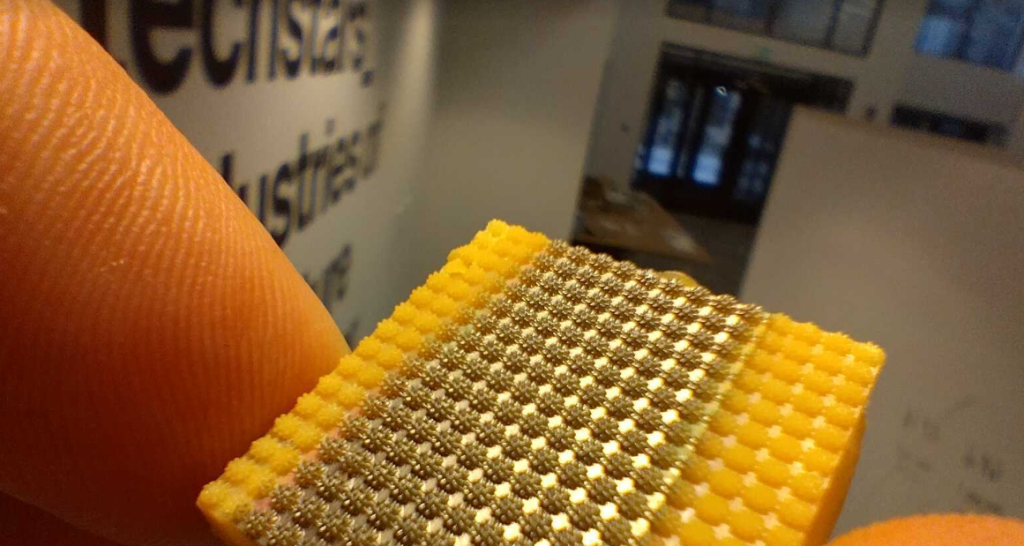

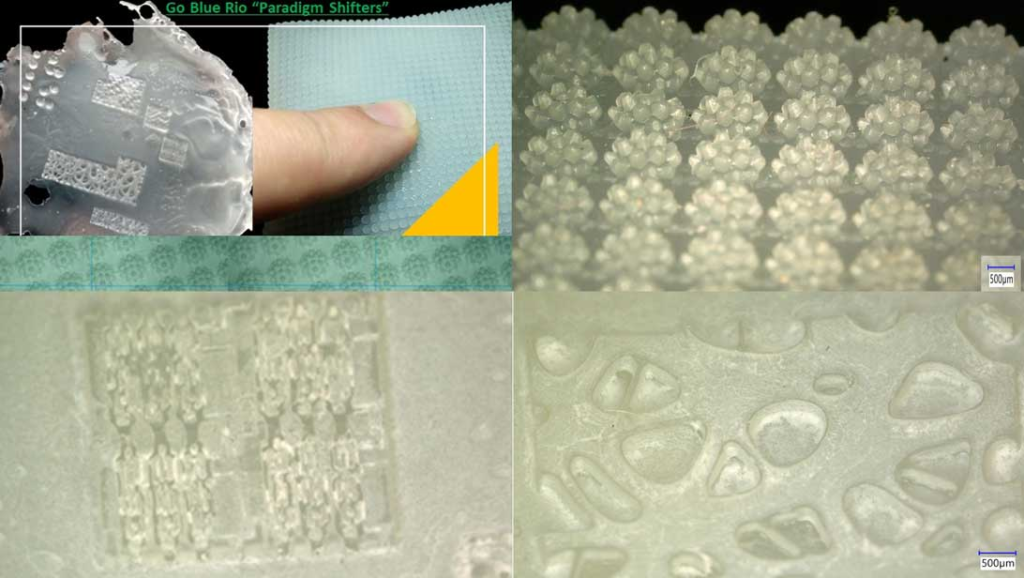

Drawing inspiration from the biomimicry of insect eyes and sacred geometric shapes, Clark has engineered an innovative solar cell that captures up to two to three times more power at almost half the cost of conventional silicon-based cells.

Clark’s journey to innovation began in 2010 with “vertical gardening,” a technique that involves cultivating plants in vertically stacked layers. By integrating vertical 3D hydroponics, he was able to distribute water and the plants evenly, resulting in a 300% increase in plant yield. It was this concept of maximizing utility in a constrained space that led Clark to wonder about its potential applications in 3D solar energy.

To explore this transition further, Clark pursued higher education, bolstered by a green stimulus aimed at promoting solar energy in educational institutions. Despite achieving a 4.0 GPA and completing all his credits, he decided against obtaining his degree. As someone with dyslexia, Clark found traditional academic settings not as interesting as a start-up and preferred a more tactile approach to learning—through hands-on invention and application of his innovative ideas.

Clark’s decision to leave academia behind has not hampered his success. Over the years, he has secured multiple patents in the 3D printing realm, including those related to volumetric solar energy, volumetric 3D printing, and a novel method for molding and casting 3D printing resin embedded with glass, metal, and ceramics—a technique currently being utilized by the likes of Glassomer and Fraunhofer, and in volumetric 3D printing by Xolo in Germany.

So, he set out to fix it. He designed and engineered his first 3D solar design here, then shrunk it so he could mass manufacture it cheaper than Chinese Solar Cells.

Acknowledging the shortcomings of the existing solar panel industry—such as cost, inefficiency, and the limitations imposed by centralized power supplies, as well as the restrictive size and shape of panels—Clark has set out to rectify these issues. He successfully miniaturized his 3D solar cell design which can be assembled into 3D solar modules.

“Think – Honey I Shrunk the Kids, but to a micro level,” Clark said.

It worked. Not just kind of, but really well.

“The more you can increase the surface area of these solar cells, naturally the more energy you capture,” he said.

3D Solar has not only enhanced energy capture due to increased surface area but also revolutionized the system to operate independently of centralized grids to help starving children in third-world countries that lack water and electricity.

Unlike traditional panels, which are susceptible to the “Christmas light effect” where one shaded panel can affect the entire array, Clark’s solar modules remain functional even with minimal sunlight, akin to the diffuse light in regions in the spring seen in the Netherlands and TN.

3D Solar’s modules are designed for decentralization and independence, allowing for parallel wiring and the compatibility of pairing different wattage panels within a single system. Despite the effectiveness of his innovation, Clark joined the Techstars cohort to elevate his product, forge vital connections, and raise the capital necessary to expedite manufacturing.

Shortly after joining the program, Clark connected with Vitriform 3D, a start-up within the Innovation Crossroads program at Oak Ridge National Laboratory. This potential partnership could see Clark using Vitriforms glass waste for use in his micro solar cell manufacturing—a sustainable practice aligning perfectly with his vision.

The most significant challenge for 3D Solar is securing the funding for the efficient conformal coating of the micro 3D solar cells. Thanks to advanced electrochemistry and a partnership with Jim Barker at ArtCraft Plating, Clark is on the path to mass production. Historically, companies like BP Oil utilized electrochemistry to commercialize flat CdTe solar modules—Barker was part of this pioneering work. However, BP’s flat modules were limited to 110 watts per m², whereas Clark’s Micro 3D Solar Cells/Modules can achieve up to 220-330 watts per m².

To reach his goal and attain UL Certification, Clark is working towards raising $1.5-2 million. With a campaign launching soon, he aims to gather about $500,000 in capital.

He’s on his way. Clark recently secured a spot in the RadLaunch 2024 class, the program is aimed at connecting technology start-ups to UV and EB industry leaders.

As he prepares for Techstars Demo Day, Clark is also exploring future programs like SPARK, Innovation Crossroads, and The CO.LAB Sustainable Mobility Accelerator powered by gener8tor. He’s currently inviting connections in the clean energy sector and is looking to hire a Solar Cell Fabrication Engineer to join his groundbreaking venture.

Techstars Demo Day is set for 4 to 8 p.m. EDT June 6 at Regas Square, 333 West Depot Avenue, and the public is invited. To register, click here

Like what you've read?

Forward to a friend!